Introduction: In the realm of modern architecture and design, the utilization of painted aluminium sheets has gained significant traction. Renowned for their exceptional durability, aesthetic appeal, and versatility, these sheets have become a preferred choice for a myriad of applications. Ever wondered how these remarkable painted aluminium sheets are produced? Join us as we take you on a comprehensive journey through the fascinating world of a painted aluminium sheet factory.

Understanding the Painted Aluminium Sheet Factory: A painted aluminium sheet factory is a sophisticated industrial establishment that specializes in the production of coated aluminium sheets, meticulously designed to meet the demands of diverse industries. These factories employ cutting-edge technology and a streamlined manufacturing process to ensure the creation of top-quality painted aluminium sheets that cater to various needs.

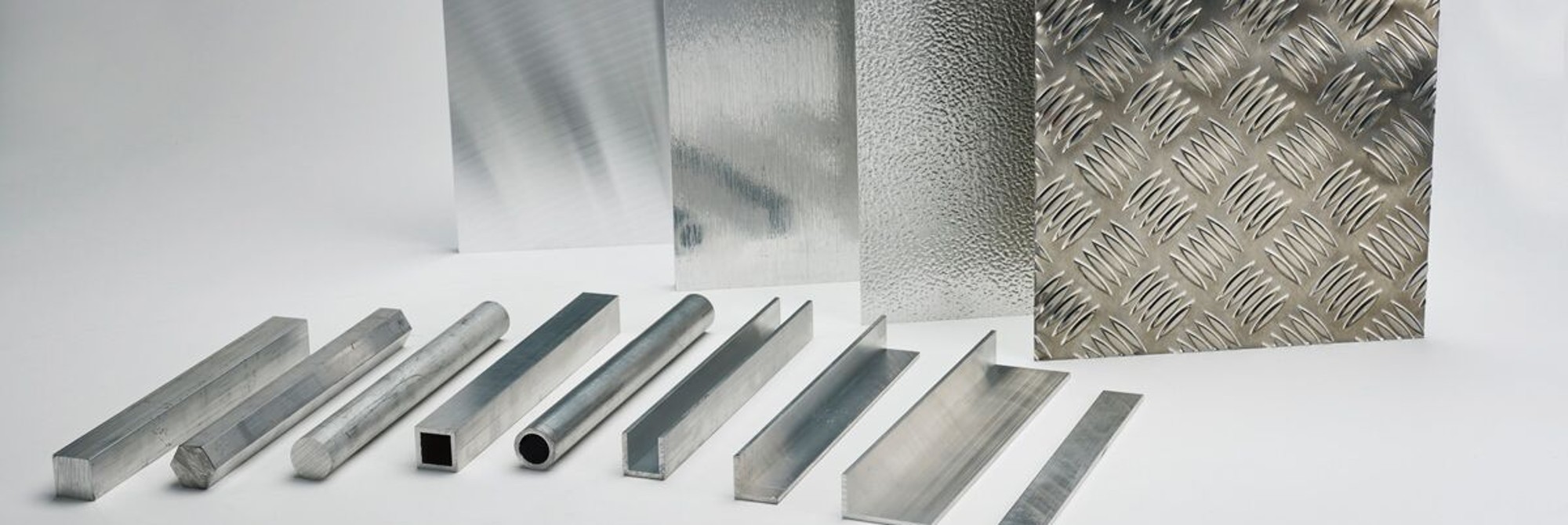

Step 1: Production Process The process of crafting painted aluminium sheets involves several key stages, each contributing to the final product’s quality and performance. The factory begins by sourcing high-grade aluminium coils, which serve as the foundation for the sheets.

- Surface Preparation: The aluminium coils undergo thorough cleaning and surface preparation to eliminate impurities and contaminants. This crucial step ensures optimal paint adhesion and long-lasting finishes.

- Primer Application: A specialized primer is applied to the cleaned surface. This layer enhances the adhesion of the subsequent paint layers and provides additional corrosion resistance.

- Coating Application: State-of-the-art technology is employed to apply the desired paint or coating onto the primed aluminium surface. This step involves precision control of coating thickness, ensuring uniform coverage.

- Curing and Baking: The coated aluminium sheets are then subjected to a controlled curing and baking process. This process ensures the fusion of the paint onto the surface, resulting in a resilient and vibrant finish.

Step 2: Quality Assurance To guarantee the excellence of the final product, painted aluminium sheet factories implement rigorous quality control measures. Comprehensive testing, including adhesion tests, color consistency checks, and corrosion resistance assessments, is conducted to ensure that each sheet meets stringent industry standards.

Step 3: Packaging and Distribution Once the painted aluminium sheets pass quality control assessments, they are meticulously packaged to prevent damage during transportation. Proper packaging also preserves the aesthetic and functional integrity of the sheets. These sheets are then distributed to various industries, including construction, automotive, aerospace, and interior design.

Step 4: Application and Versatility Painted aluminium sheets find application in an array of industries and projects. Their remarkable durability, corrosion resistance, and aesthetic appeal make them ideal for exterior building facades, interior decorations, signage, automotive body panels, and even electronic gadgets.

Step 5: Sustainability Considerations A notable aspect of painted aluminium sheets is their sustainability. Aluminium is highly recyclable, and the manufacturing process can be optimized to minimize waste and energy consumption. This aligns with the growing emphasis on eco-friendly materials and practices in contemporary industries.

Conclusion: The painted aluminium sheet factory plays a pivotal role in shaping modern architecture and design. With a meticulous production process, stringent quality control, and a commitment to sustainability, these factories ensure the creation of top-tier painted aluminium sheets. These sheets, with their captivating aesthetics and exceptional durability, continue to enhance various industries and contribute to the evolution of innovative and sustainable solutions.

Link: Painted Aluminium Sheet Factory

As you embark on your next architectural or design endeavor, remember the intricate craftsmanship and technological marvel that go into producing the remarkable painted aluminium sheets that elevate the visual and functional aspects of contemporary creations.