Introduction: In today’s dynamic manufacturing landscape, Computer Numerical Control (CNC) machinery has revolutionized the way industries produce high-quality, complex parts. The ability to automate processes using CNC machines has led to increased precision, faster production rates, and reduced human error. In this blog post, we will delve into the world of CNC machinery parts, exploring their significance, types, and benefits.

Step 1: Understanding CNC Machinery Parts

- What are CNC Machinery Parts? CNC machinery parts refer to the components used in Computer Numerical Control machines. These machines operate using pre-programmed computer software to control the movement and operation of various cutting tools, drills, and other equipment. CNC machinery parts are essential elements that make up the machine and play a crucial role in determining the quality and efficiency of the manufacturing process.

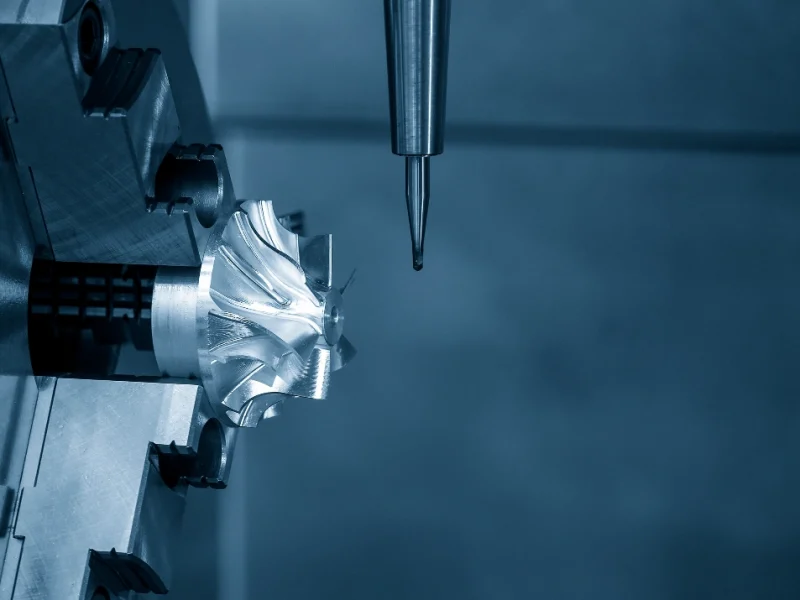

- Types of CNC Machinery Parts a. Spindle: The spindle is a rotating component responsible for holding and driving the cutting tool. It determines the speed and accuracy of the cutting process.

b. Axis: CNC machines can have multiple axes (X, Y, Z, etc.) that define the directions in which the cutting tool can move. Each axis contributes to the machine’s ability to create intricate shapes and contours.

c. Tooling: Tooling includes various cutting tools, such as end mills, drills, and lathes, which are used to shape the workpiece according to the programmed design.

d. Workholding Devices: Workholding devices secure the workpiece in place during the machining process. Examples include chucks, vises, and fixtures.

e. Control Panel: The control panel houses the interface through which operators can input instructions, set parameters, and monitor the machining process.

- Importance of Quality CNC Machinery Parts The quality of CNC machinery parts directly impacts the overall performance of the CNC machine. High-quality parts ensure greater precision, stability, and longevity of the machine, leading to consistent and accurate results. Additionally, reliable CNC parts reduce downtime, maintenance costs, and the risk of production errors.

Step 2: Advantages of CNC Machinery Parts

Investing in high-quality CNC machinery parts brings a plethora of benefits to manufacturers:

- Enhanced Precision: CNC machinery parts enable the production of intricate and complex designs with unparalleled precision, meeting the most stringent industry standards.

- Higher Efficiency: With automated processes and faster cutting speeds, CNC machines equipped with quality parts can significantly increase production rates and reduce lead times.

- Consistency and Reproducibility: The use of reliable CNC machinery parts ensures consistent and repeatable results, reducing variations and defects in the final products.

- Reduced Labor Costs: Automated CNC machinery parts require minimal human intervention, leading to reduced labor costs and increased productivity.

- Flexibility: CNC machines can be easily reprogrammed to accommodate design changes or produce different parts, offering manufacturers greater flexibility in their operations.

Step 3: Conclusion

In conclusion, CNC machinery parts play a pivotal role in the success of modern manufacturing processes. These essential components, including the spindle, axes, tooling, workholding devices, and control panels, work together to achieve precision and efficiency in CNC operations. By investing in high-quality CNC machinery parts, manufacturers can unlock a world of possibilities, ranging from intricate part designs to increased productivity and cost savings.

As technology advances and AI continues to shape the manufacturing landscape, the integration of AI-driven optimization in CNC machinery is expected to further elevate precision, speed, and productivity, making CNC machining an indispensable tool for industries worldwide.