Introduction

Welcome to our blog post on the importance of manufacturing and distribution in the supply chain! In today’s fast-paced world, where efficiency and speed are paramount, harnessing the power of an effective supply chain is a crucial aspect for businesses across industries. And at the heart of this intricate web lies manufacturing and distribution. Whether it’s producing goods or ensuring their smooth delivery to customers, these two elements play a vital role in driving success for companies worldwide.

But why exactly are manufacturing and distribution so important? What benefits do they bring to the overall supply chain? And what challenges do they face along the way? Join us as we delve into these questions and explore how these integral components shape the landscape of modern-day business operations. So let’s dive right in!

The Role of Manufacturing and Distribution in the Supply Chain

Manufacturing and distribution play a crucial role in the supply chain of any industry. These two components are like the backbone that supports the entire process, ensuring goods reach their intended destination efficiently and on time.

In manufacturing, raw materials are transformed into finished products through various processes. This step requires careful planning, coordination, and quality control to ensure consistent output. Manufacturers need to have efficient production lines, skilled workers, and advanced technology to meet customer demands effectively.

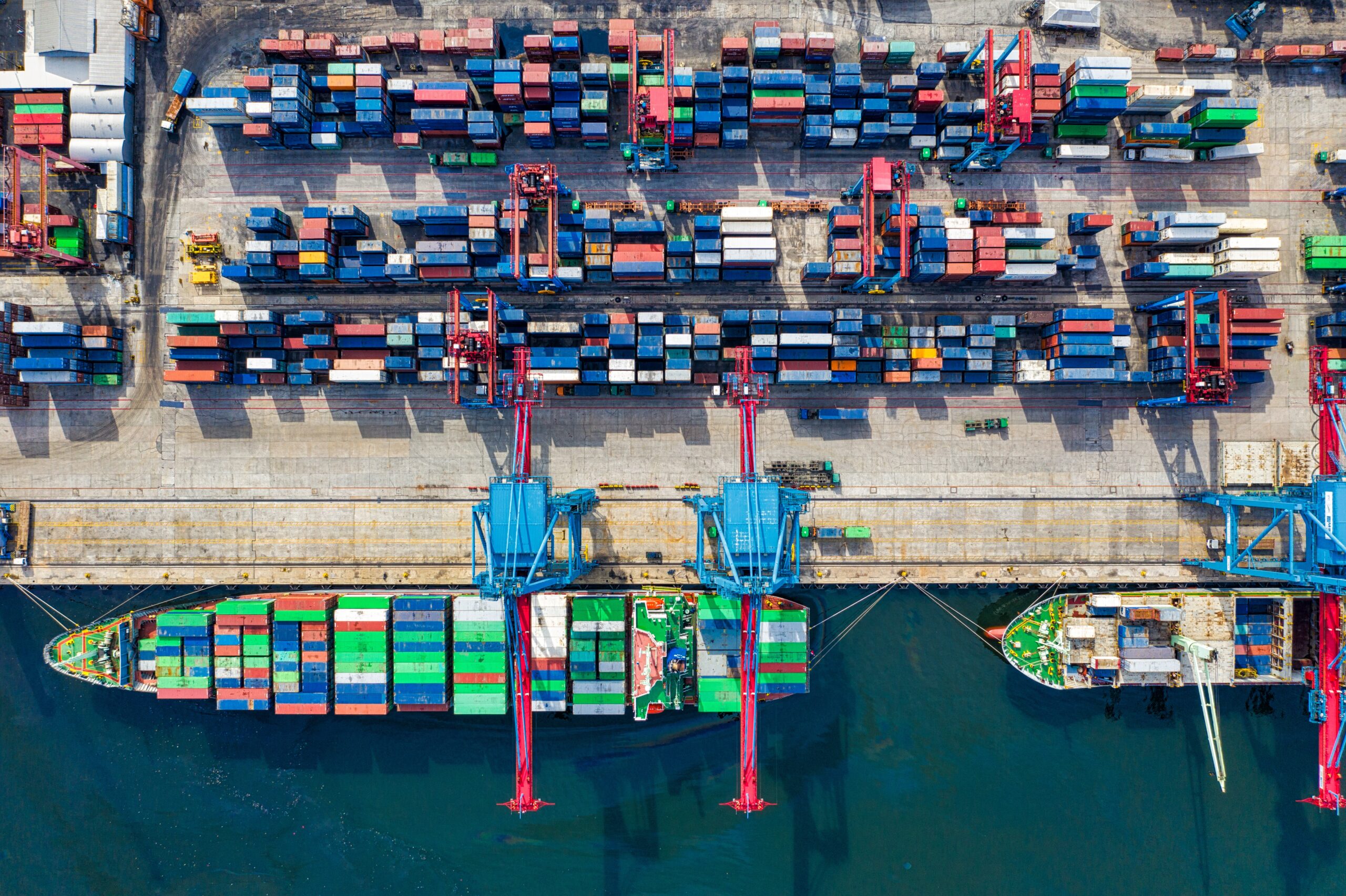

Once the products are manufactured, they need to be distributed to retailers or directly to customers. Distribution involves activities like warehousing, transportation logistics, inventory management, and order fulfillment. The goal is to get the right product at the right place at the right time.

Effective manufacturing and distribution processes help optimize inventory levels by minimizing stockouts while reducing excess inventory costs. It also ensures speedy delivery of goods which leads to improved customer satisfaction.

Moreover, best pharmaceutical companies in Hyderabad have built robust manufacturing facilities equipped with state-of-the-art technology for producing high-quality drugs.

Their efficient distribution networks allow them to deliver medicines promptly across India.

These companies strive for excellence in every aspect of their operations, resulting in reliable supply chains that benefit patients nationwide.

In conclusion, the role of manufacturing and distribution in the supply chain cannot be underestimated.

It is essential for businesses not only to survive but thrive in today’s competitive market.

Manufacturers must focus on continuous improvement while distributors should prioritize speed, reliability, and cost-efficiency.

Working together seamlessly, a strong manufacturing-distribution partnership can create a resilient supply chain capable of meeting consumer demands effectively

The Benefits of Manufacturing and Distribution in the Supply Chain

Manufacturing and distribution play a crucial role in the supply chain, offering numerous benefits to businesses. One of the key advantages is increased efficiency. By having manufacturing facilities strategically located near distribution centers, companies can streamline their processes and reduce lead times. This ensures that products reach customers in a timely manner, enhancing customer satisfaction.

Another benefit of manufacturing and distribution in the supply chain is cost savings. By producing goods closer to where they will be distributed, companies can minimize transportation costs and reduce inventory holding expenses. Additionally, by optimizing production schedules based on demand forecasts, manufacturers can avoid overproduction or stockouts.

Furthermore, manufacturing and distribution contribute to improved quality control. With operations happening under one roof or within close proximity, it becomes easier for manufacturers to monitor product quality throughout the entire process – from raw material sourcing to final packaging.

Having effective manufacturing and distribution capabilities also allows businesses to respond quickly to market demands. They have the flexibility to adjust production volumes based on fluctuations in customer preferences or market trends. This agility enables companies to stay competitive in dynamic industries.

Moreover, an integrated approach to manufacturing and distribution fosters collaboration between different departments within an organization. Teams involved in these functions work closely together, sharing insights and knowledge that lead to continuous improvement across the supply chain.

In conclusion (non-conclusive), integrating robust manufacturing and efficient distribution practices into the supply chain brings multiple advantages including enhanced efficiency, cost savings through reduced transportation expenses and optimized inventory management techniques. Improved quality control measures ensure consistent product quality while responsiveness allows businesses to adapt swiftly according t

The Challenges of Manufacturing and Distribution in the Supply Chain

Manufacturing and distribution play a crucial role in the supply chain, ensuring that goods are produced and delivered to customers efficiently. However, this aspect of the supply chain also presents its fair share of challenges.

One major challenge is managing inventory effectively. Indian Pharmaceutical companies need to strike a balance between having enough stock to meet demand while avoiding excessive inventory that ties up capital. Accurate forecasting is key but can be difficult due to factors such as changing customer preferences or unexpected disruptions.

Another challenge is maintaining quality control throughout the manufacturing process. Consistently producing high-quality products requires strict adherence to standards and protocols. Any deviation from these standards can result in product defects, customer dissatisfaction, and potential recalls.

In addition, coordinating logistics across multiple locations can be challenging. Distributing products from manufacturing facilities to various warehouses or retail outlets requires careful planning and coordination with transportation providers. Delays or disruptions in shipping can lead to increased costs or missed delivery deadlines.

Furthermore, global supply chains face additional complexities such as navigating international regulations and customs processes. This involves understanding different trade policies, complying with documentation requirements, and dealing with potential delays at border checkpoints.

Technological advancements bring their own set of challenges. While automation and digitization have improved efficiency in manufacturing and distribution processes, they also require ongoing investment in infrastructure upgrades and training for employees.

Despite these challenges, manufacturers must adapt by embracing technology solutions like data analytics for better forecasting accuracy or implementing lean principles for more efficient operations. Collaboration within the supply chain ecosystem is essential for overcoming obstacles together.

Conclusion

In this article, we have explored the importance of manufacturing and distribution in the supply chain for best pharmaceutical company in india. We have seen how these two crucial components play a vital role in ensuring that products reach consumers efficiently and effectively.

Manufacturing is responsible for transforming raw materials into finished goods. It involves various processes such as procurement, production planning, quality control, and packaging. By having strong manufacturing capabilities, companies can ensure consistent product quality and timely delivery to meet market demand.

Distribution, on the other hand, focuses on getting products from manufacturers to end-users. This includes activities like warehousing, transportation management, order fulfilment, and customer service. Efficient distribution networks enable businesses to deliver their products quickly and accurately to customers across different regions.

The benefits of manufacturing and distribution in the supply chain are numerous. First and foremost is improved customer satisfaction. When products are manufactured efficiently and distributed effectively, customers receive them promptly without any disruptions or delays. This leads to higher levels of customer satisfaction and loyalty.

Another benefit is cost reduction. By streamlining manufacturing processes and optimizing distribution channels, companies can minimize expenses associated with inventory holding costs, transportation fees, and storage expenses.